You Reliable One-stop Services Partner

With our high-quality prototyping, low-volume manufacturing and massive manufacturing services, we help you bring your product ideas to life. Our experienced engineers will collaborate with you using manufacturing technologies such as CNC turning, CNC milling, plastic injection molding, sheet metal fabrication, 3D printing and various finishing services.

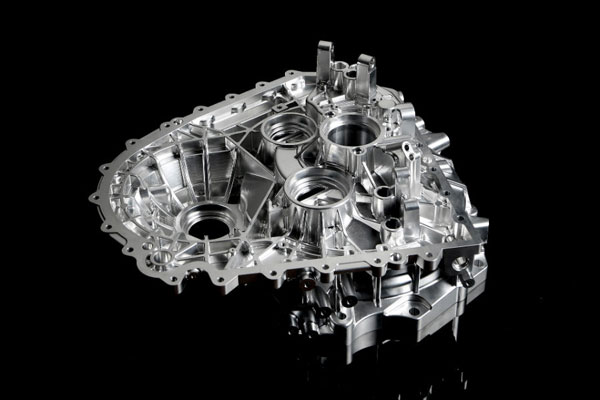

We can mill steel and stainless steel, aluminum, brass, and hardened steels with high accuracy and precision for your most challenging applications.

We can turn and turn-mill steel and stainless steel, aluminum, brass, and hardened steels with high accuracy and precision for your most challenging applications.

Our services for production are flexible and fast in volume from one part to millions. We don’t have any restrictions on the minimum order.

We can make world-class tools and parts for production in unlimited quantities. We offer family molds, and insert molding for your most demanding projects.

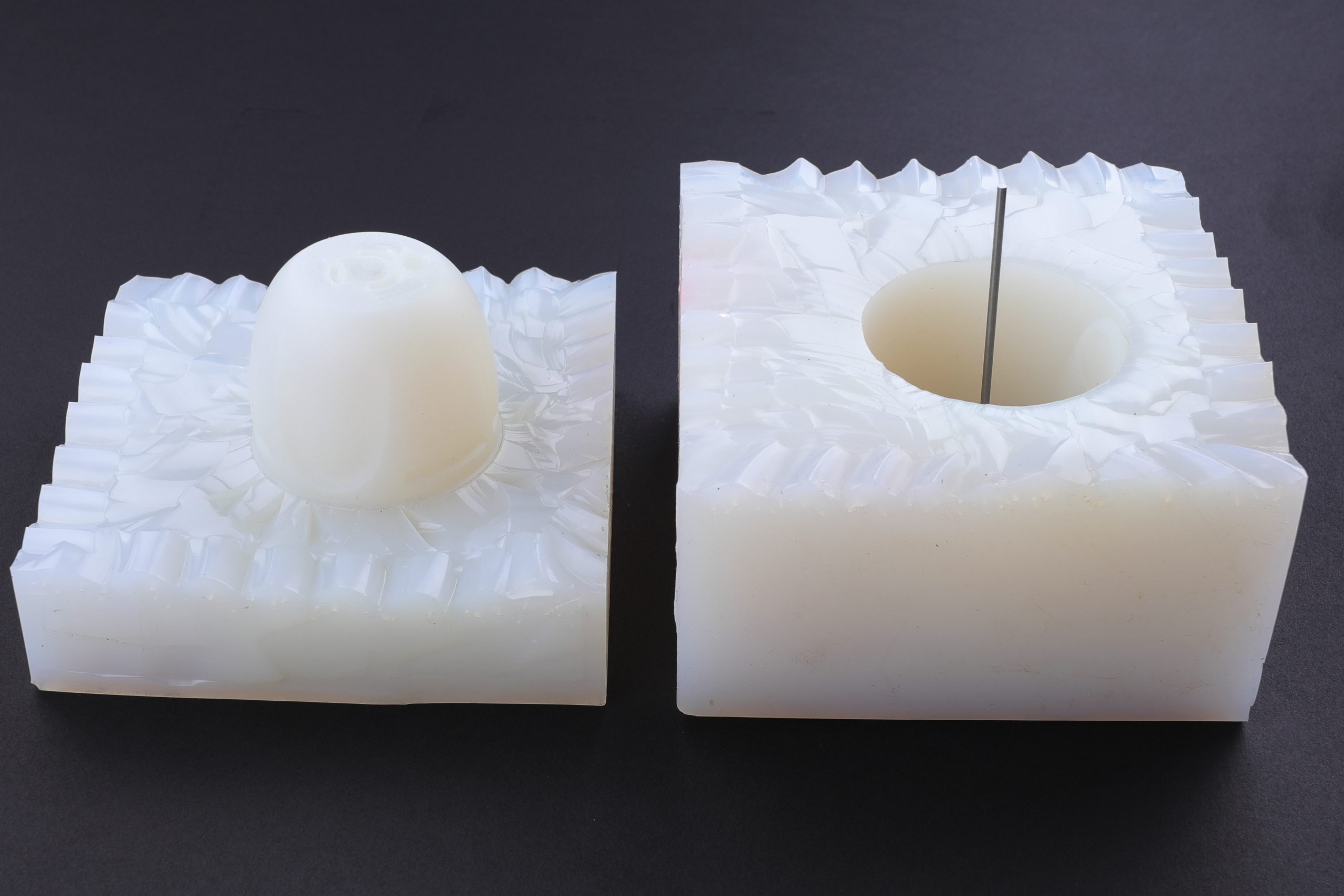

3D printing is a good option for both creating prototypes and producing in low volume. The machining turn-around is usually very short because of its machining features.

We offer highly complex pressure die cast tools and finished parts in magnesium, zinc, and aluminum.

Our parts come with a range of finishing options to suit your needs, such as paint, plate, anodize, polish, and more.

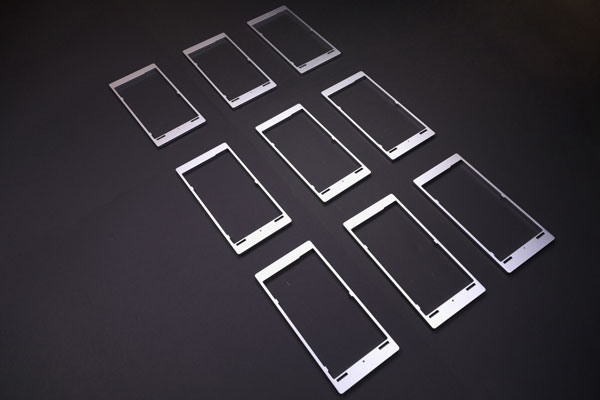

We offer sheet metal fabrication and CNC cutting services for both creating prototypes quickly and producing your parts in low to high volumes.

Convincing Manufacturing partner you can rely on

At Crown, we are committed to providing a superior level of service that is tailored to your specific requirements. Our sales engineers assist you throughout the process, from the beginning of product design to the final stage of mass production.

500+ Companies served

60+ countries/regions shipped

5M unique parts produced

15 years manufacturing experience

10 years global trading

How to start your projects with Crown?

1. Quotation

Upload your drawings, 3D files and describe your requirements or contact our sales engineers directly. Your will get:

(1) Free quotation within 24 hours

(2) DFM suggestions

2. Production

After you issued the PO, we will start production strictly according with ISO quality management system.

3. Receive your custom parts

After the parts are fully passed quality inspection, we will securely package the parts and ship them to you. As well, we provide a 1 year quality assurance for all parts after sales.

Strength of Crown

Crown helps you realize your concept with excellent on-demand manufacturing services. We produce simple and complex prototypes and final parts with powerful and efficient manufacturing capabilities. We meet strict tolerance and quality standards for all our products, making us the best on-demand manufacturing factory in China.

- ISO 9001:2015 Certificated factory

- Fast response

- Wide range of services for you to choose

- Sufficient production capability

- Better service quality – this also leads to more deliveries being on time

- Less need for returns – because problems are detected and solved faster, often without the customer noticing

- Service guarantee – certification shows that the organisation offers consistent, reliable and suitable solutions

Crown has skilled service engineers who can answer all your manufacturing questions within 24 hours. Our expert engineers give you professional guidance and DFM feedback that helps improve your design, reduce cost, and achieve better or more consistent quality control through standardization. Our competent staff is always ready to provide excellent engineering support for you.

Crown provides you with accurate fabrication of plastic and metal parts in any quantity. We excel in multi-axis milling, turning, EDM, surface grinding, laser engraving, 3d printing, injection moulding and much more. Moreover, you can be sure that all raw materials will match your exact requirements because of our top-notch testing and verification laboratory. That’s one of many reasons why we are a trusted supplier to world-class companies for their most challenging prototype and volume production projects.

Crown uses the best materials and the latest technologies to create products from design to production. Our factory has all kinds of machining, such as CNC lathes, milling centers, injection molding machines, advanced 3D printing equipment, and more. Our highly skilled and experienced technicians work 24/7 to ensure the best product quality.

Let's Start a New Project Today

Crown Quality for Your Parts

Advanced machines, accurate inspection equipment and experienced stuff will be the barrier of quality. From material suppliers chain management, processing standard to final quality inspection, we make sure customers are well involved at every step during the manufacturing process.

Keep innovation during manufacturing and provides the best solution for you to help you save cost and shorten production turnaround. One-stop machining service for your different order requests.

Industries we served

Crown delivers fast, high-quality, customized solutions for leading companies in various industries. Our quality management system and experience guarantee quality in every project. We know the requirements of your industry and work with you to meet and exceed them.

Automobile

Automatic

Aerospace

Medical

Electronics

Robotics

Foods

Semiconductor

Cooperated partners & reputations

A customer’s testimonial is more powerful than a company’s statement – and see how our happy customers have praised how we met their needs.

Blogs

Guideline of choosing material for CNC machining parts/ prototypes.

When considering CNC machining costs, designers must factor in various elements to minimize expenses. Among these factors is the selection of appropriate machining metals, which impacts both cost and production efficiency. Every company aims to reduce costs while...

Guideline of CNC milling parts

CNC milling is a subtractive manufacturing process that uses a rotating cutting tool to remove material from a workpiece. It is a versatile process that can be used to create a wide range of parts, from simple to complex. This guideline provides some general design...

The most important things in plastic injection molding.

Inject molding is known as a manufacturing process that is very useful in producing parts in large volume. Plastic injection molding is used in the mass production process where there is a production of same things or parts thousands and million times in a succession....

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China