Design for manufacturability (DFM) of sheet metal

The first consideration when designing a sheet metal part is whether it can be manufactured using the available processes and tools. This means designing for features that can be easily formed, cut, and welded.

Bend radius

The bend radius is the minimum radius to which a piece of sheet metal can be bent without cracking. The bend radius should be as large as possible to prevent cracking and to ensure that the part can be formed without distortion.

Bend relief

Bend relief is a small amount of extra material that is added to the inside of a bend to prevent the metal from cracking or tearing. The amount of bend relief required will depend on the thickness of the material and the severity of the bend.

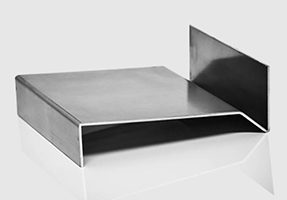

Flanges

Flanges are used to add strength and rigidity to a sheet metal part. They can also be used to provide a mounting surface for other components.

Beads

Beads are raised ribs that are formed into the sheet metal. They are used to add strength and stiffness to a part, and they can also be used to improve the appearance of a part.

Tabs and slots

Tabs and slots are used to connect two pieces of sheet metal together. They are typically formed by punching or laser cutting the sheet metal.

Holes

Holes can be punched, drilled, or laser cut into sheet metal. The size and location of the holes should be carefully considered to ensure that they do not weaken the part.

Clearances and tolerances

Clearances and tolerances are important to consider when designing a sheet metal part. Clearances are the spaces between different parts of the assembly, and tolerances are the allowable variations in the dimensions of a part.

Material selection

The material selection for a sheet metal part will depend on the application. Common sheet metal materials include aluminum, steel, and stainless steel.

Surface finish

The surface finish of a sheet metal part can be smooth, rough, or painted. The surface finish should be selected to meet the requirements of the application.

Cost

The cost of a sheet metal part will depend on the complexity of the part, the material selection, and the quantity of parts required.

Additional considerations

In addition to the above guidelines, there are a number of other factors to consider when designing a sheet metal part. These factors include:

- The grain direction of the material

- The direction of the bend

- The use of stiffeners

- The use of embossing and debossing

- The use of fasteners

By following these guidelines, you can design sheet metal parts that are manufacturable, functional, and cost-effective. Please view our service ‘sheet metal‘ for more information.