When considering CNC machining costs, designers must factor in various elements to minimize expenses. Among these factors is the selection of appropriate machining metals, which impacts both cost and production efficiency. Every company aims to reduce costs while ensuring swift movement of parts from production to market.

Different metals suitable for CNC machining possess distinct mechanical properties, such as strength, flexibility, and corrosion resistance. These properties influence machinability, with some metals being easier to work with than others.

Typically, metals with higher machinability are more economical due to quicker processing times. However, raw material costs also play a significant role in overall expenses.

This article explores how material choice, particularly metals, affects machining costs. Let’s delve into some of the most cost-effective metals for CNC machining:

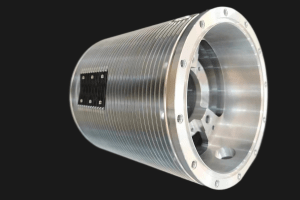

- Aluminum: Available in various alloys, aluminum ranks among the most cost-effective metals for CNC machining due to its high machinability and relatively low raw material cost. Its strength-to-weight ratio, corrosion resistance, and temperature resistance make it widely used across industries like aerospace, automotive, and healthcare.

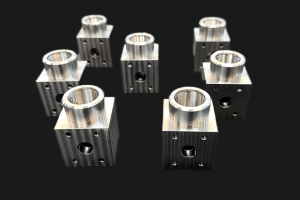

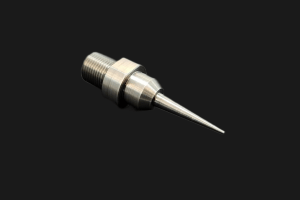

- Stainless Steel: Stainless steel, offered in different alloys, is a popular material for CNC machining. While not as machinable as aluminum, it still maintains good machinability relative to its cost. With properties like high strength and chemical resistance, it finds applications in automotive, aerospace, and food industries.

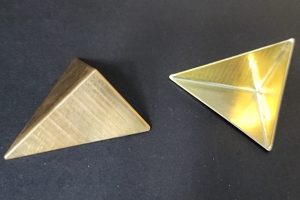

- Brass: Brass, an alloy of copper and zinc, offers high machinability, making it cost-effective despite a slightly higher raw material cost. Its applications span across electrical goods, consumer goods, and architecture due to its medium hardness and high tensile strength.

- Copper: Copper boasts very high machinability, making it cost-effective for CNC machining despite its higher raw material cost. Its applications range from automotive to consumer electronics due to its good electrical and thermal conductivity.

- Titanium: Titanium, though costly, offers unique properties like high strength-to-weight ratio and excellent corrosion resistance, making it suitable for specialized industries like aerospace and medical.

Various factors, such as manufacturing time, environmental suitability, weight, strength requirements, and post-processing treatments, influence the choice of cost-effective CNC machining metals.

In conclusion, selecting the right CNC metal is crucial for minimizing costs without compromising quality. Collaborating with experienced manufacturers like Crown Part can help in making informed decisions.