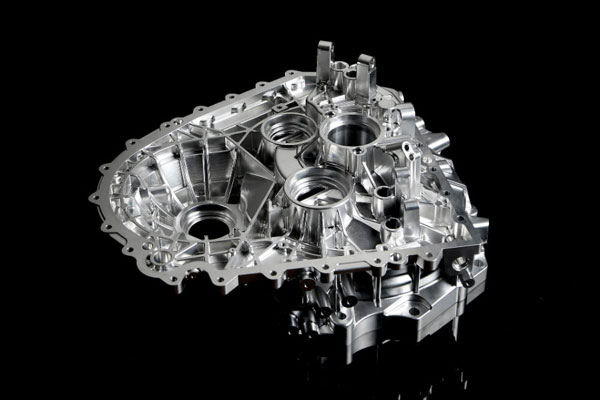

Die Casting

What do Die Casting products do:

Die casting products are light industrial parts with precise size, beautiful appearance, and solid and durable materials. The parts produced by die-casting technology are favored by the industry due to their exquisite appearance, precise size, strong durability, and high efficiency in mass production.

What are the Die Casting materials:

Commonly used materials for Die Castings The main alloy materials for Die Castings are tin, lead, zinc, aluminum, magnesium, copper, etc., zinc and aluminum alloys are widely used. Die-casting aluminum alloys can be used in industries such as radiators, aluminum shells, pots, pot covers, lighting, automotive engines, electric tool shells, and electrical appliances. Die-cast zinc alloy is mostly used in hardware products, bicycle accessories and other fields.

Application fields of die-casting aluminum:

- Hardware Accessories

- Aerospace

- Vehicle accessories

- Construction industry

- Machine, equipment, automation line

- Military industry

- Communication

- Electronic

Advantages of our product details:

- Strict material selection

It is made of high-quality raw materials, meets the standards that has good weather resistance, is durable, and is not easy to deform.

- Rigorous workmanship

The company has many years of industry experience, the process is strictly controlled, the surface can be shot blasted, smooth and burr-free, with a metallic texture.

- Support customization

Various specifications can be customized according to customer requirements, customized according to drawings and samples, and the delivery cycle is short.

Customized service process

- Consult our engineer to understand customization needs

- Provide quotation according to demand

- Create a contract

- Pay mold advance payment

- Build molds and deliver modules

- Pay casting advance payment

- Mass production

- Grinding and sandblasting

- Machining

- Surface treatment

- Pay the balance of the casting

- Shipping and delivery, receipt confirmation

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Industry-Leading CNC machining equipment

Imported 5-axis CNC machining centers running the most advanced AutoDesk and Vericut software. Exclusive Guhring cutting tools from Germany for the finest tool performance and longevity.

Intelligent pricing for every CNC machining project

Offering you a proprietary, patent-pending AI quotation algorithm. The power of machine learning gives you fast and accurate CNC machining quotes without guesswork.

Comprehensive raw material testing and verification

No one in the industry offers more dependable positive material identification (PMI). You can proceed with full confidence that your parts will meet all of your material specifications and regulatory compliance requirements.

A full suite of finishing services

Most CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.