Low Volume Production

What does low-volume manufacturing mean?

Low-volume manufacturing is a service that provides parts with the same quality as mass production, but in smaller quantities, usually up to 100,000 pieces or less, depending on the method used. This service is suitable for products that need to adapt to the changing market demands and shorten development cycles. Crown can help you with this service.

How can low-volume manufacturing be done?

Some customers may think that low-volume manufacturing means sacrificing quality or accuracy compared to full-scale production. But you can trust us, we use the same materials, equipment and quality standards for small batch orders.

Crown has a reliable source of raw materials and is dedicated to delivering products that meet your design and specifications. We constantly improve our production management, process optimization, supply chain cooperation and cost control, and strive to increase customer satisfaction with fast, efficient and competitive prices. Here are some of the low-volume manufacturing services we offer:

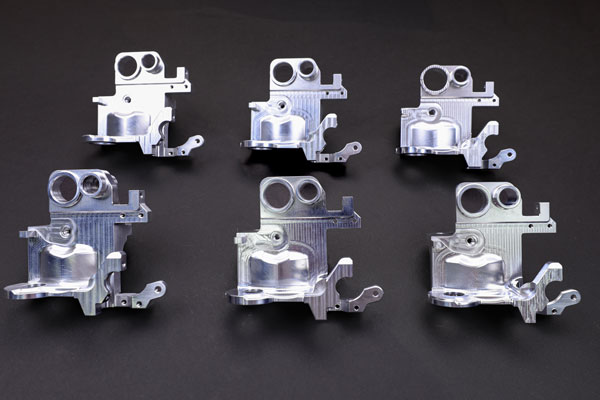

(1) CNC machining: We use our advanced 3, 4 and 5-axis CNC machines to make CNC milling and turning parts for low-volume production.

(2) Rapid injection molding: Rapid tooling is ideal for customers who need small batch parts. Injection molding can also produce thousands of parts with the same design.

(3) Vacuum molding: We use 3D printing or CNC machining to make silicone molds for small batch production. This way, you can test the functionality and evaluate the pre-production of your parts without spending too much time and money on plastic injection mold tools.

The benefits of low-volume manufacturing

Why should you choose low-volume manufacturing? Here are some reasons:

- It allows you to make design changes easily. Low-volume manufacturing gives you the flexibility to improve your design based on customer feedback or market trends. You can make changes without affecting the whole order.

- It bridges the gap between rapid prototyping and mass production.

- It reduces the time and cost of bringing your products to the market. You can deliver your products in days or weeks instead of months.

- It saves you money, lowers your financial risk and avoids having outdated products in stock.

Let's Start a New Project Today

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Extensive Range of In-House Services

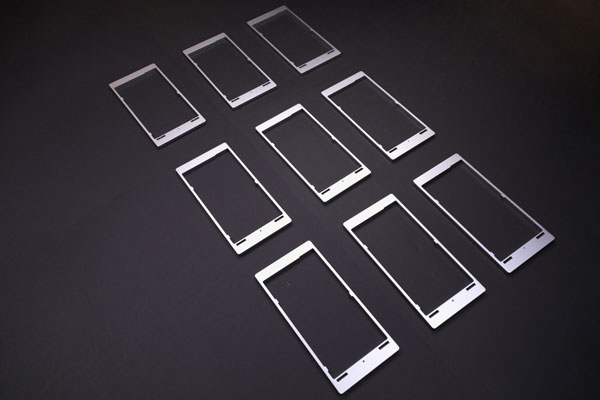

To meet the diverse low-volume production needs of our worldwide partners, our team proudly provides a wide range of in-house manufacturing services including CNC milling, CNC turning, Sheet metal, 3D printing, vacuum casting and Injection molding.

Cost break down and remote reports

In contrast to prototyping, low volume production also requires large cost break down to fit the market and consumers. Our engineers will help you achieve this by production optimization and provide you the report how we achieved.

Parts assembly support

We strictly control the incoming material and request material certificate. For special alloy material supplied by material suppliers, we will do a XRF test to guarantee we used the correct material.

A full suite of finishing services

Most CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.