Rapid Prototyping

- As fast as 3 days.

- Direct factory price.

- High quality guarantee.

- Tight tolerance.

- Complex features.

- Special material.

- Free DFM.

Rapid Prototyping Services

Rapid prototyping is the process of creating a physical sample of a new product design concept. It is a useful way to check if the final product will have the desired appearance, feel, and performance. New product designers use rapid prototyping for various purposes. They can test the functionality, get approvals, make design changes, show models at trade shows, and prepare for low-volume manufacturing.

Prototypes can help improve the design by revealing flaws, enhancements, and other changes that might not be evident from a computer graphic. Therefore, they can save time and money by avoiding design mistakes before moving to larger production volumes. The cost of the prototype can be offset by the benefits of optimizing the design early in the development stage.

Crown Part Prototyping Services

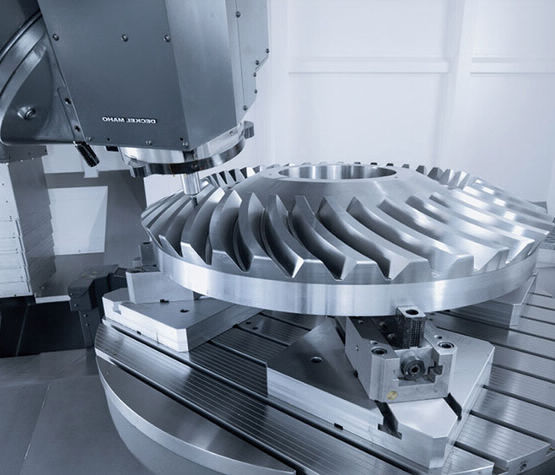

CNC Milling protoryping

CNC Turning Prototyping

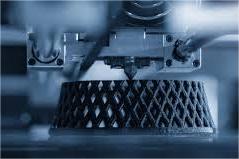

3D Printing Prototyping

Sheet Metal Prototyping

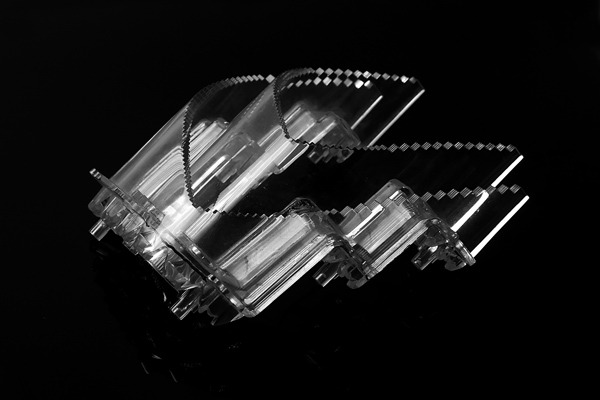

Injection Molding Prototyping

How does prototyping be finished?

Rapid prototyping is not a single technology or method. It can use any of the manufacturing techniques that are also used for regular production volumes.

The key is to make a physical model that resembles the design goal, is strong, can be made quickly, and does not require a lot of tooling or raw materials.

Crown Part can help you achieve your prototypes by: CNC milling, CNC turning, 3D printing, injection molding, sheet metal fabrication etc. based on actual application of your products.

Wide surface finishing to choose:

We provide wide range of surface finish: as machined, brush, media blasting, polishing, anodizing, heat treatment, passivation, oxide, painting, coating etc.

Different types of prototyping

Concept Model

This is one of the simplest types of prototypes. Also called a proof-of-concept prototype, engineers use the concept model to convey the basic idea of the design. Before use, this type of prototype undergoes multiple changes.

Display Prototype

Engineers develop this type of prototype to make it look similar to the final product. Most times, functionality is not a factor considered under the display prototype as the focus is mainly on appearance.

Functional Prototype

This prototype focuses on functionality and aims to enable engineers and designers to test the product to make modifications if any, for optimal functionality. The prototype developed here should behave the same way as the final product.

Pre-Production Prototype

This is the last type of prototype developed before production. There are two major purposes of this type of prototype. First, to validate the process chosen by the manufacturer for mass production, and second, to ensure the manufactured part functions optimally.

Tips for you to choose right prototyping

Define Your Objectives: Clearly define your prototyping goals. Are you aiming to test functionality, assess aesthetics, or validate user experience? Understanding your objectives will help you choose the most suitable prototyping method.

Consider Complexity: Assess the complexity of your design. Some prototyping methods are better suited for simple designs, while others excel at handling intricate features and details.

Budget Constraints: Evaluate your budget limitations. Different prototyping methods vary in cost, with some being more affordable for small-scale projects or individuals, while others are more suitable for larger budgets or corporate environments.

Time Constraints: Consider your timeline. Some prototyping techniques offer rapid turnaround times, ideal for quickly iterating and testing concepts, while others may take longer but provide higher fidelity prototypes.

Material Properties: Understand the properties of the materials available for prototyping. Different materials offer varying levels of strength, durability, flexibility, and appearance, so choose one that aligns with your project requirements.

Iterative Approach: Embrace an iterative prototyping process. Start with low-fidelity prototypes to explore concepts and gradually refine them based on feedback and testing results.

User Feedback: Involve end-users in the prototyping process whenever possible. Their feedback and insights can uncover design flaws, usability issues, and areas for improvement early on, saving time and resources in the long run.

Scalability: Consider the scalability of your prototyping method. Will it be feasible to scale up production if your prototype receives positive feedback and moves towards mass production?

Environmental Impact: Evaluate the environmental impact of your prototyping method. Opt for materials and processes that minimize waste, energy consumption, and environmental footprint whenever possible.

Benefits Of Rapid Prototyping

How can working with Crown to quickly create a prototype benefit you and your business?

Here are some examples:

- Present your customers and investors with a physical model of your product

- Show the appearance, size, and features of your product

- Test the market with your product before production

- Save time and money by finding and fixing design flaws

- Improve and simplify the production process

- Create different versions with different colors, surface textures, and finishing processes

Let's Start a New Project Today

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Industry-Leading machining equipment

We imported advanced equipment from Japan and EU to guarantee the tolerance and quality. Exclusive milling tools from Germany for the finest tool performance and longevity.

Wide range of material for you to choose

To meet the clients requirements, we have over 70 kinds of material for you to choose including engineering plastic, copper, steel, stainless steel, aluminum, titanium and other special alloy.

Fast production and delivery

Except the price and quality, lead time is also crucial in prototyping. We can guarantee 1-5 days for simple parts and 5-12 days for complex parts.

Various finishing services

Mechanical parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.