Material and Tolerance

Materials

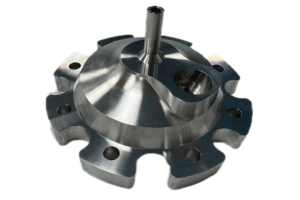

- CNC Machining Metals

- CNC Machining Plastics

- Injection Mold Tooling

- Injection Molding Plastics

- Sheet Metal Fabrication

- 3D Printing Plastics

| Materials | Image | Description | Price |

More Infos |

| Aluminum |

|

High strength-to-weight ratio |

$ |

NA |

|

Stainless steel |

|

Good corrosion resistance + High Hardness |

$$$$ |

NA |

| Steel |

|

Good machinability + Excellent electrical conductivity |

$$$ |

NA |

| Brass |

|

Good machinability + Excellent electrical conductivity |

$$ |

NA |

| Copper |

|

>99.3% Purity + Superior electrical conductivity |

$$ |

NA |

| Titanium |

|

Corrosion resistance + High tensile strength |

$$$$$ |

NA |

| Materials | Image | Description | Price |

More Infos |

|

ABS |

|

High stability + Easy to process |

$$ |

Learn More |

|

POM (Delrin) |

|

Low-friction + High-stiffness |

$$ |

Learn More |

|

PC (Polycarbonate) |

|

High impact resistance + High transparency |

$$$ |

Learn More |

|

PA (Nylon) |

|

High chemical and heat resistance + High abrasion and wear resistance |

$$ |

Learn More |

|

PMMA (Acrylic)

|

|

High transparency + Good chemical stability |

$ |

Learn More |

|

PEEK |

|

High-performance thermoplastic, very high strength, thermal and chemical resistant. |

$$ |

Learn More |

|

PP (Polypropylene) |

|

Excellent chemical resistance. Food-safe grades available. |

$ |

Learn More |

|

PE (Polyethylene) |

|

Excellent strength-to-weight ratio, impact and weather resistant. |

$$ |

Learn More |

| Materials |

Image |

Description |

Price |

More Infos |

|

Aluminum |

|

High machinability and ductility, good strength-to-weight ratio. |

$ | Learn More |

|

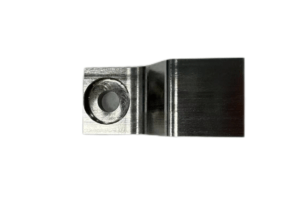

Tool Steel |

|

High hardness and stiffness, abrasion resistant. |

$$$ |

Learn More |

| Materials |

Image |

Description |

Price |

More Infos |

| ABS |

|

High stability + Easy to process |

$$ |

Learn More |

|

POM (Delrin) |

|

Low-friction + High-stiffness |

$$ |

Learn More |

|

PC (Polycarbonate) |

|

High impact resistance + High transparency |

$$$ |

Learn More |

|

PA (Nylon) |

|

High chemical and heat resistance + High abrasion and wear resistance |

$$ |

Learn More |

|

PMMA (Acrylic) |

|

High transparency + Good chemical stability |

High transparency + Good chemical stability |

Learn More |

| PEEK |

|

High-performance thermoplastic, very high strength, thermal and chemical resistant. |

$$ |

Learn More |

|

PP (Polypropylene) |

|

Excellent chemical resistance. Food-safe grades available. |

$ |

Learn More |

|

PE (Polyethylene) |

|

Excellent strength-to-weight ratio, impact and weather resistant. |

$$ |

Learn More |

|

Materials |

Image |

Description |

Price |

More Infos |

| Aluminum |

|

High strength-to-weight ratio\ Aerospace components |

$ |

Learn More |

| Copper |

|

>99.3% Purity + Superior electrical conductivity |

$$$$ |

Learn More |

|

Stainless steel |

|

Good corrosion resistance + High Hardness |

$$ |

Learn More |

|

Steel |

|

Good machinability + Excellent electrical conductivity |

$ | Learn More |

| Materials | Image | Description | Price |

More Infos |

|

Nylon |

|

High chemical and heat resistance + High abrasion and wear resistance |

$$ |

Learn More |

| ABS |

|

High stability + Easy to process |

$ | Learn More |

| PLA |

|

High stiffness, good detail, affordable. |

$ |

/ |

| Resin |

|

High detail and smooth surface, injection mold-like prototyping. |

$$ |

/ |

Tolerance

At Crown, our tightest machining tolerance for both prototype and production parts is +/- 0.005 mm. This means that any dimension or feature of the part will not vary more than this amount from the nominal value. For instance, if you order a bracket that is 25 mm wide, it will measure between 24.9995 and 25.005mm in width.

Depending on the shape and material of the part, the tolerance will be varied. Before we start the project we will confirm with you about the requirements. Though, we can meet this tightest tolerance, we will provide you several solutions to fulfill your requests and help you save cost.

Normally speaking, the design will require tight tolerance in key positions such as fitting surfaces. For unimportant surface and features, ISO-2768 standard is a good reference (table below):

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| 0.5 up to 3 | ±0.05 | ±0.1 | ±0.2 | / |

| over 3 up to 6 | ±0.05 | ±0.1 | ±0.3 | ±0.5 |

| over 6 up to 30 | ±0.1 | ±0.2 | ±0.5 | ±1.0 |

| over 30 up to 120 | ±0.15 | ±0.3 | ±0.8 | ±1.5 |

| over 120 up to 400 | ±0.2 | ±0.5 | ±1.2 | ±2.5 |

| over 400 up to 1000 | ±0.3 | ±0.8 | ±2.0 | ±4.0 |

| over up 1000 to 2000 | ±0.5 | ±1.2 | ±3.0 | ±6.0 |

| over up 2000 to 4000 | / | ±2.0 | ±4.0 | ±8.0 |

| Permissible deviations in mm for ranges in nominal lengths | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| 0.5 up to 3 | ±0.2 | ±0.2 | ±0.4 | ±0.4 |

| over 3 up to 6 | ±0.5 | ±0.5 | ±1.0 | ±1.0 |

| over 6 | ±1.0 | ±1.0 | ±2.0 | ±2.0 |

| Permissible deviations in degrees and minutes for ranges in nominal length | Tolerance class designation (description) | |||

| f (fine) | m(medium) | c(coarse) | v(very coarse) | |

| up to 10 | ±1º | ±1º | ±1º30′ | ±3º |

| over 10 up to 50 | ±0º30′ | ±0º30′ | ±1º | ±2º |

| over 50 up to 120 | ±0º20′ | ±0º20′ | ±0º30′ | ±1º |

| over 120 up to 400 | ±0º10′ | ±0º10′ | ±0º15′ | ±0º30′ |

| over 400 | ±0º5′ | ±0º5′ | ±0º10′ | ±0º20′ |

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.