3D Printing

What is 3D printing?

3D printing, also known as additive manufacturing, is a set of processes that use CAD files (usually STL) to create 3-dimensional parts. Objects are built up layer by layer using different materials and methods of bonding them together. Plastics and metal alloys are the most common materials for 3D printing, but 3D printing can work with almost anything from concrete to living tissue. 3D printing parts and products can be found in various aspects of life, and the use of 3D printing services has also stimulated the innovation and progress of many industries.Crown is also willing to contribute to these industries with its own strength.

Types of 3D printing

- SLS (Selective Laser Sintering) The materials used are nylon, metal powder, PS powder, and resin sand. The powder is fused together rather than being melted into a liquid state. Under laser scanning, the part is formed layer by layer, and finally, the part is supported by unfused powder from each layer, which is distributed throughout the build volume until each layer is joined together. The high accuracy, relatively low-cost raw materials and high temperatures that this technology can achieve make it a very useful technology with a wide range of applications, from architectural models to aircraft control surfaces and surgical tools.

- SLA (Stereolithography) Stereolithography, or SLA, is a 3D printing technique known for producing highly detailed and functionally accurate parts that uses an excess of liquid plastic that eventually hardens into a solid product, using photosensitive resins. Focus the laser with specific wavelength and intensity on the surface of the photo-curable material to make it solidify from point to line and from line to surface to complete the drawing of one layer. The lift table then moves one layer vertically to cure the other. These layers are stacked to form a three-dimensional solid.

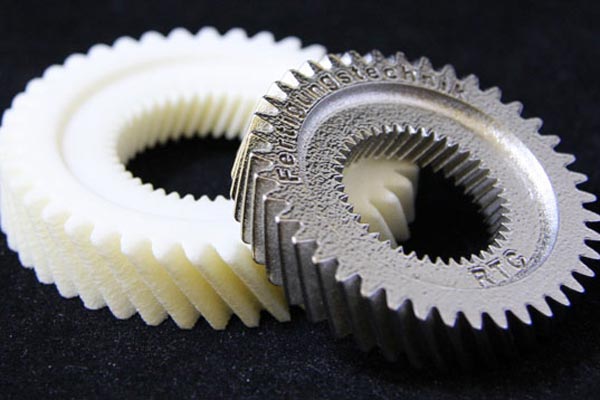

- FDM (Fused Deposition Modeling) Fused deposition modeling (FDM) is a 3D printing technique, also known as additive manufacturing, commonly used for modeling, prototyping, and production applications. Each layer is created by extruding material through a nozzle to create a 3D object.The materials used are polylactic acid and ABS plastic. It is worth noting that whether separable or soluble, this process requires a support material, so it is important to keep this in mind when choosing this process as it will affect the final part. (4) SLM (Selective Laser Melting) SLM is the main part of the metal 3D printer, and the materials used include titanium alloy, cobalt-chromium alloy, stainless steel, aluminum alloy, etc. In SLM technology, under the action of high-energy laser, the metal powder is completely melted, and after cooling and solidification, it is metallurgically welded with the base metal, and then accumulated layer by layer to form a three-dimensional parts.

The difference between metal materials and plastics Material

Machining tolerance, also called dimensional accuracy, is the acceptable amount of variation in the size of a part. Regarding CNC machining, tolerances are used in two different contexts: in terms of CNC machine and in terms of CNC machining design. During the enquiry, we would like to share our experience of tolerance for design-for-manufacturing if you need it. Those suggestions will be based on:

- Review the geometric tolerance. Sometimes too many geometric tolerances will affect the shape of the workpiece.

- Orientation tolerance. It is the total amount of change allowed in the direction of the reference actual element relative to the reference, including parallelism, perpendicularity, and angularity.

- Location tolerance. Before we put the part onto the 5 Axis machine, we will check out the correct location tolerance.

- Run–out tolerance. It’s also the machining tolerance during the process we care about.

Let's Start a New Project Today

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Free DFM support and suggestions

Our team of experienced 3D engineers providing personalized guidance for every project. Resolve complex design challenges, enhancing print success and customer satisfaction, according to your unique specifications.

One stop and in-house manufacturing services

We have various 3D printing equipment to help you achieve your projects by our in-house production from molds production to products production.

Incoming raw material testing and verification

We strictly control the incoming material and request material certificate. For special alloy material supplied by material suppliers, we will do a XRF test to guarantee we used the correct material.

A full suite of finishing services

Most 3D printed parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.