CNC Milling Service

Crown Parts CNC Milling Service

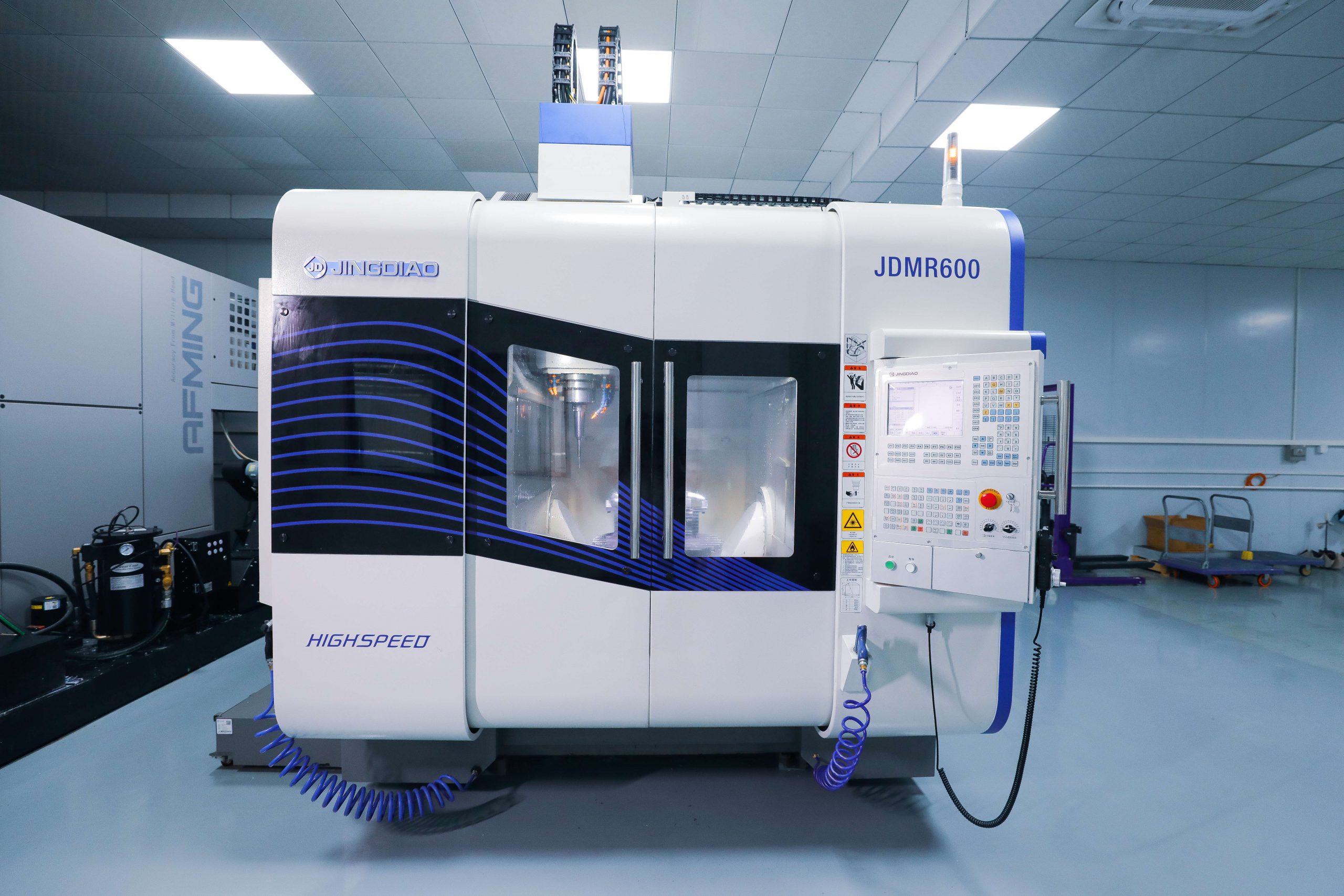

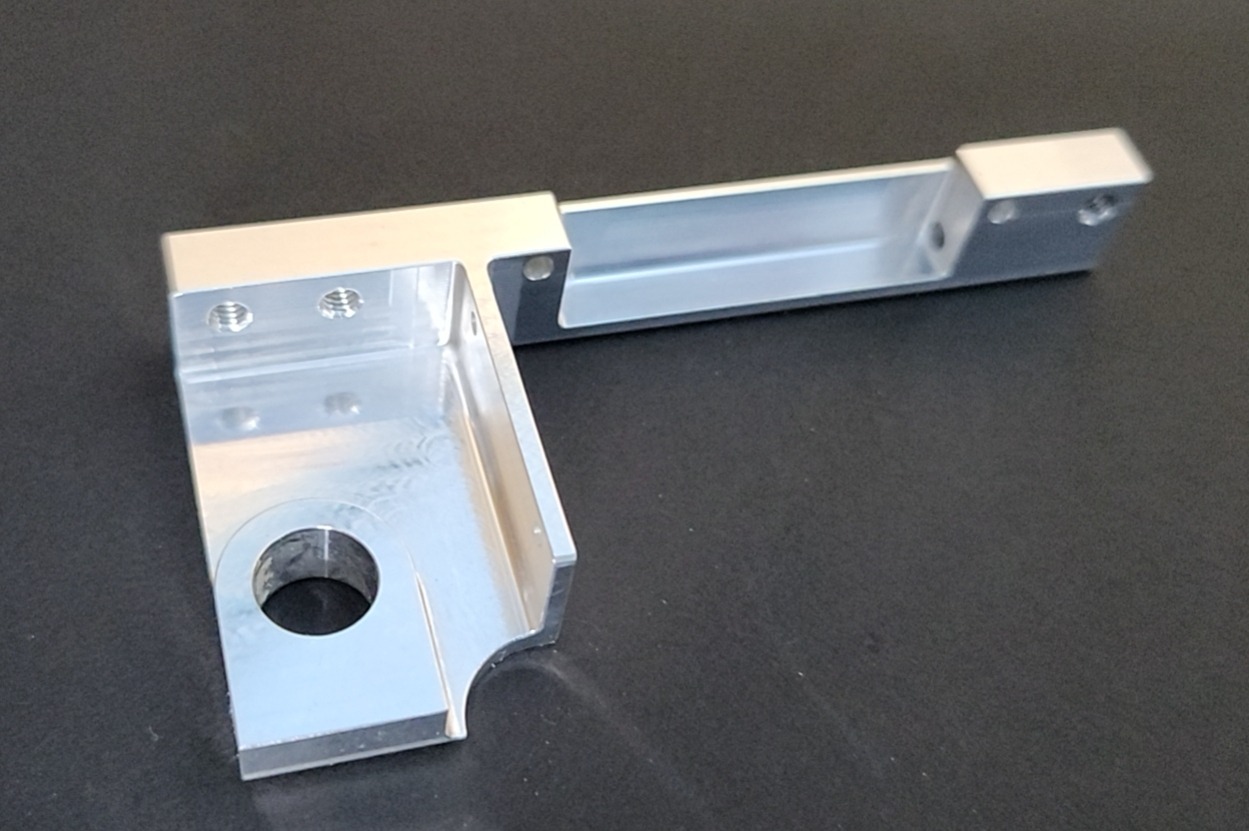

Crown Part’s CNC milling services are dedicated to creating complex geometries and features on plastic and metal parts for prototyping and low-volume manufacturing. We have 30 five-axis high precision CNC machines and more than 80 CNC machining centers.

Our CNC milling services are designed to complement our many other fabrication and finishing capabilities for your low volume needs, providing a complete, fast turnkey solution for your next project.

What Is CNC Milling?

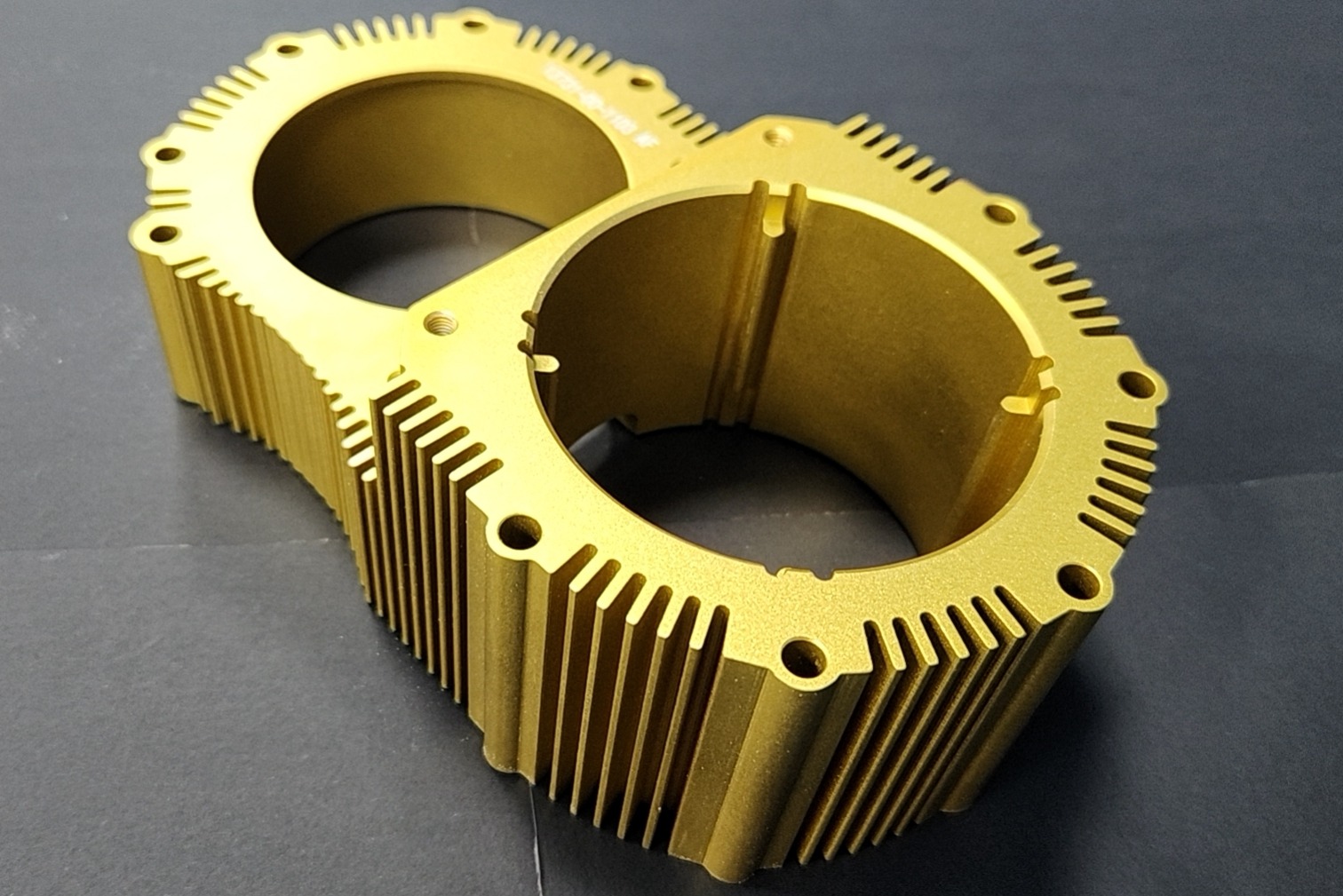

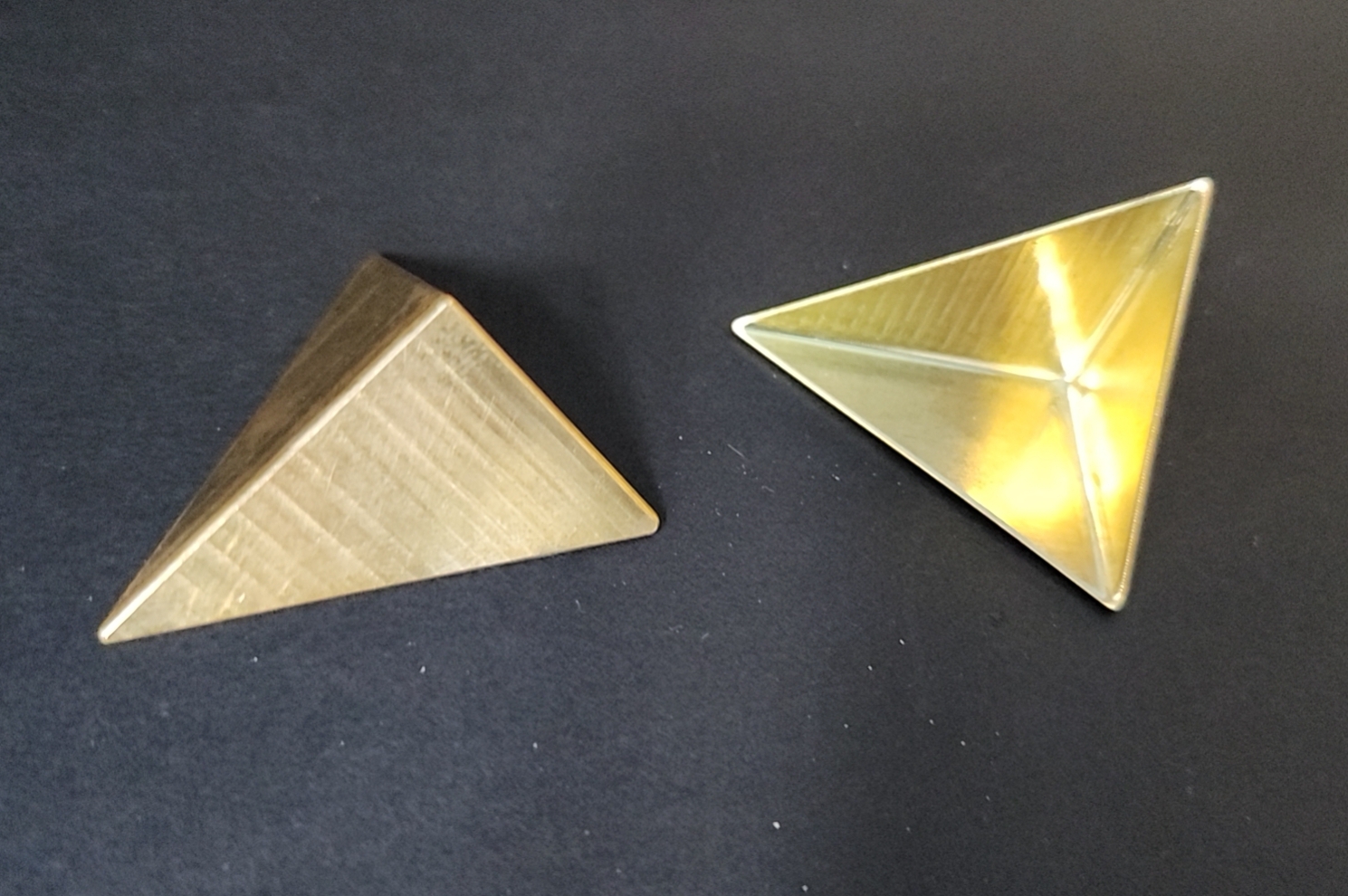

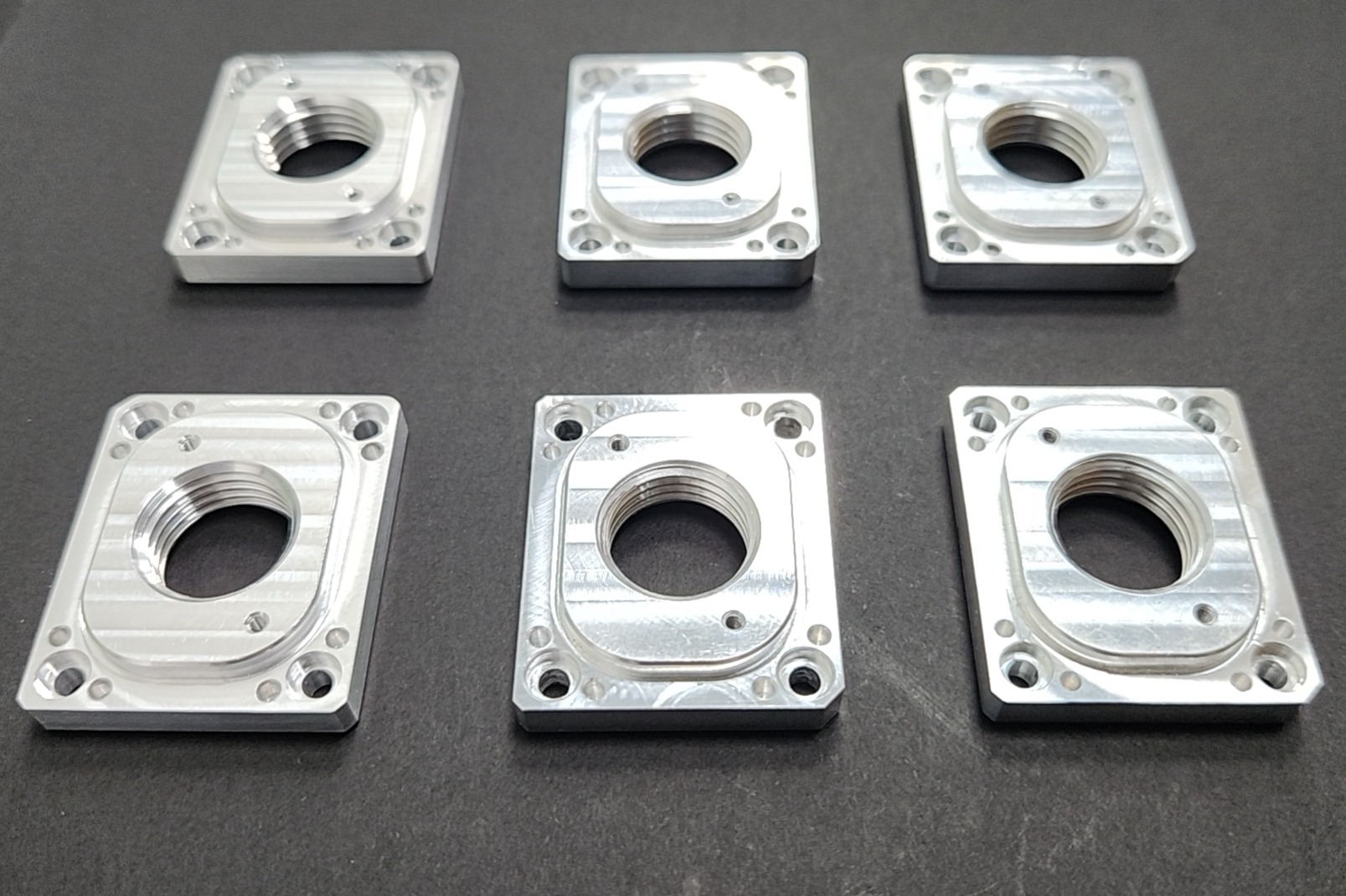

CNC milling is a process that creates final parts from solid blocks of plastic and metal by subtractive processing. The process follows your CAD file, which is optimized to make a physical copy of your digital design.

Milling involves various operations and machines, from small individual parts to large, heavy milling operations. It is one of the most common processes for making custom parts with precise tolerances. In CNC milling, the workpiece is fixed in a rigid vise or fixture on a table. This table can move in two axes by swiveling and pivoting. A cutting tool on a rotating spindle removes material to create different complex geometries and part features on the workpiece. A multiple-axis milling machine, such as our Hermle 5-axis milling center, has an advantage that the table and spindle can move in multiple independent axis, which provides not only accuracy and repeatability, but also versatility.

Materials That Can Be CNC Milled

Milling is a very versatile process, applicable to many materials. When selecting materials for CNC milling, many factors should be considered, such as cost and material properties. Usually choose a solid, stable material.

Here are some commonly used materials for CNC milling:

Metal

Metals and metal alloys are the most commonly used abrasive materials. This is because they are widely used in several industries. Commonly milled metals are aluminum and its alloys, various types of steel, brass, copper, titanium and bronze.

Plastic

This is followed by plastic because it is popular in many industry. They also have desirable properties and are widely used. Polymers such as ABS, PEEK, polycarbonate, and nylon are some of the plastics that are often CNC milled.

Other Materials

Wood, glass, and elastomer are also suitable materials for CNC milling.

Let's Start a New Project Today

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Advanced CNC machining equipment

We imported advanced equipment from Japan and EU to guarantee the tolerance and quality. Exclusive milling tools from Germany for the finest tool performance and longevity.

Cost-efficitive pricing for every CNC machining project

Every project from you will be carefully evaluated from DFM to final quotation by our engineers to support you in both lead time and price.

Strict raw material testing and verification

We strictly control the incoming material and request material certificate. For special alloy material supplied by material suppliers, we will do a XRF test to guarantee we used the correct material.

Various finishing services

Mechanical parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.