CNC Turning

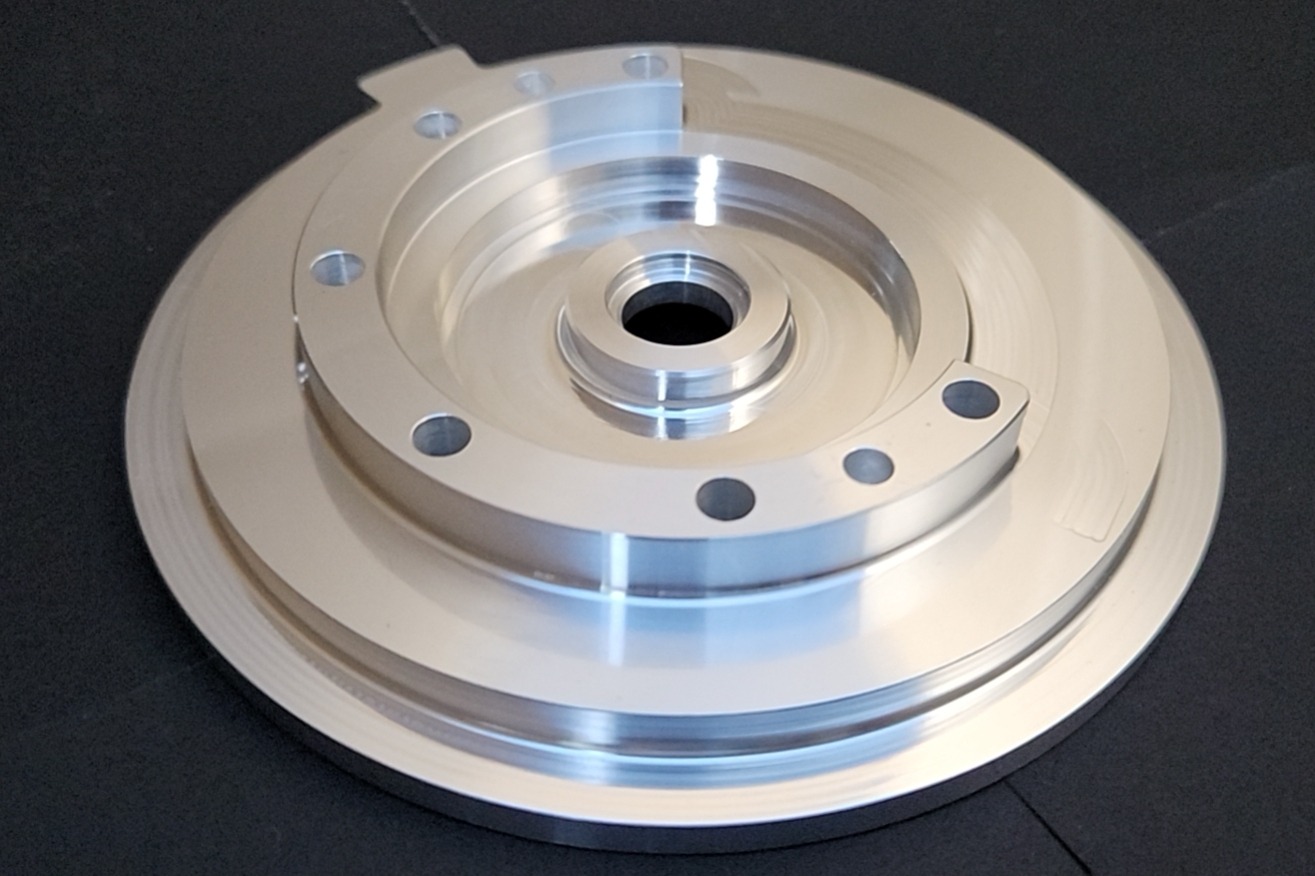

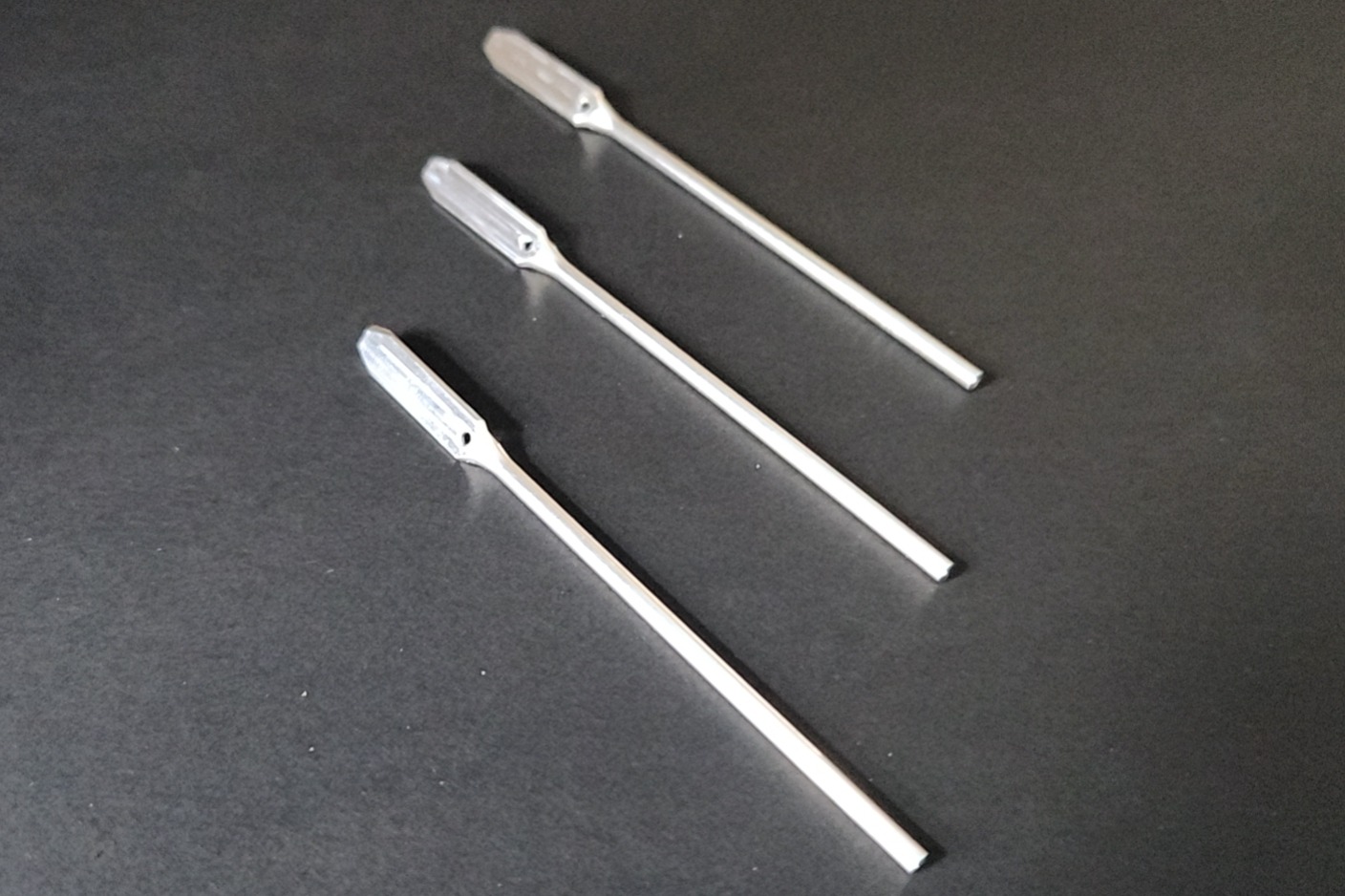

CNC Turning Service

Crown is specialized in providing most advanced CNC turning services for new products developer to complete any project. We have a standard constant temperature workshop, experienced engineer, advanced lathe equipment and imported cutting tools to ensure quality, with strict inspection in every step of production process, we ensure that it meet with your specifications .

What is CNC turning?

CNC turning is a type of precision CNC machining process that rotates a cylindrical workpiece in a chuck and cuts it with a tool to make CNC turned components with a smooth surface finish that may not need further processing. Turning can be done on the outside or inside of the workpiece to make tubular components with different shapes.

The CNC turning process is usually done on a CNC lathe or turning center. Before cutting, the turning machine and G-code have to be ready, then the bar of material is fixed in the chuck of spindle, which rotates the piece. When the spindle reaches a certain speed, a stationary single-point cutter moves along a linear path that is parallel to the rotation axis and removes extra material, reduces the diameter of the block, sets the dimension and creates smooth finish, to make final custom CNC turned parts with the required specification.

Advantages of CNC turning and tips of material use

CNC turning are capable of removing large amounts of material quickly, it does not require any post finishing to get a excellent surface when using our precision cutting tools. Turning is the only practical fastest way to make internal and external threads, long holes, tapers, ring grooves and most of the cross-section is circular.

Turning can machine any strong, stable material, of which hard plastics and metals are commonly used, such as aluminum, many mild and stainless steels, titanium, magnesium, brass, copper and other alloys. However, for some hard tool steels,it will require special handling and longer production time. When cut on a lathe or mill. Soft elastomer or plastics may also fail to turn as they can not stay in a fixed place or change in shape under the pressure of a cutting tool.

Let's Start a New Project Today

Why choose us for CNC Turning service?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Advanced CNC turning and tuning-milling compound.

Imported CNC turning equipments from USA and Japan are stable and can achieve extremly tight tolerances.

Cost-efficitive pricing for every CNC turning project

Every project from you will be carefully evaluated from DFM to final quotation by our engineers to support you in both lead time and price.

Strict raw material testing and verification

We strictly control the incoming material and request material certificate. For special alloy material supplied by material suppliers, we will do a XRF test to guarantee we used the correct material.

A full suite of finishing services

Most CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.