Finishing

Finishing Services

If you need your parts to have better protection against corrosion or a specific appearance, you should consider finishing service. It is a crucial option to make your design perfect. Crown is an experienced manufacturer of finished parts. Our workers and craftsmen can offer a variety of finishing services, such as aluminum anodizing, painting, passivating, electroplating, powder coating, polishing, black oxide, abrasive blasting, and more. Below are some introductions to different kinds of metal finishes. For more information, please contact us anytime.

Anodizing

It is an electrochemical process that forms a thin layer of metal oxide on the surface of CNC machined parts. It increases the thickness of the natural oxide layer, protects the metal, adds various colors, and enhances the resistance to corrosion and abrasion. Aluminum is the most common material for anodizing, and its benefits are well known. However, other metals can also undergo anodizing, such as stainless steel, copper, titanium, zinc, and magnesium.

Passivating

It is a typical chemical surface treatment method for steel and stainless steel. It uses a light coat of protective material to create a shell that improves the resistance to corrosion or reduces the chemical reactivity. Passivation of stainless steel removes free iron and ferrous contaminants on the metal surface with an acid solution to prevent rust.

Plating (Electroplating)

It changes the properties of the metal surface or increases the thickness for undersized parts. Chrome plating, nickel plating and more are often used at CNC LATHING.

Painting

It is the process of applying paint, pigment, or color to a solid surface as a colored protective layer. It can be done on metal or non-metal CNC machined parts of any shapes. It is usually applied on aluminum, stainless steel and steel alloy parts. The purpose is to improve the aesthetic appearance and prevent corrosion or oxidation.

Black Oxide

It is a chemical process that forms a black conversion coating on stainless steel, copper and copper based alloys, zinc, powdered metals, silver solder, and ferrous materials. The black oxide coating can improve the resistance to corrosion and reduce the reflection of light.

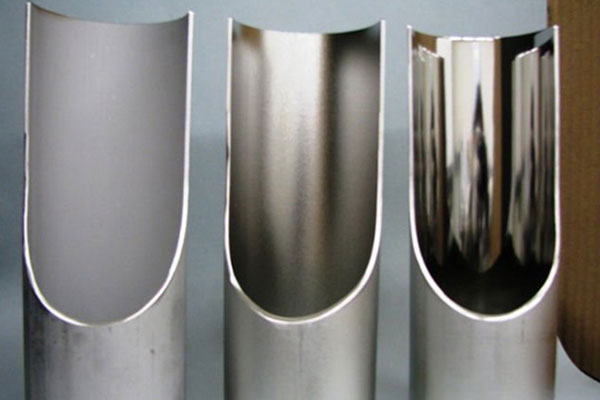

Polishing

It is a process of rubbing the surface of parts or using a chemical action to produce a smooth and shiny surface. It makes the surface have significant reflection or reduce diffuse reflection in some materials.

Powder Coating

It is the process of applying a functional and decorative finish that is applied as a free-flowing dry powder. It uses electrostatically and then cured under heat to create a hard finish that is stronger than conventional paint. The main applications include household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

Heat treatment

It is the process of using heating or chilling under extreme temperatures to make the metal achieve a certain state or change some characteristics. Heat treating techniques include annealing, tempering, hardening, precipitation strengthening, tempering, normalizing and quenching.

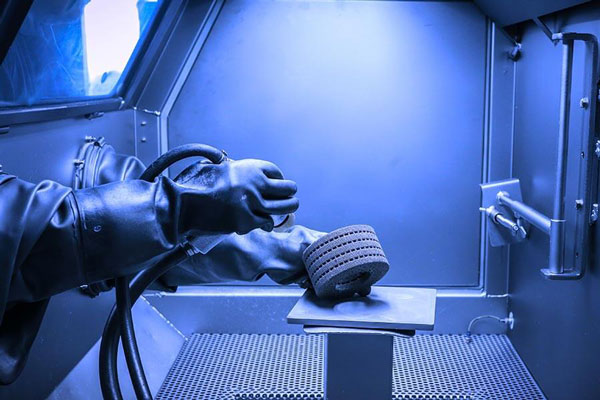

Abrasive blasting (Sandblasting)

It is the operation of propelling a stream of abrasive material composed of high-velocity sand-sizes particles against the metal surface under high pressure with blast equipment like air pressure system. It removes surface contaminants cleans metals or increases a texture then changes the smoothness or roughness of surface.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.