Injection Molding Services

Crown Parts Injection Molding Services

Crown Part is a world-class provider of advanced injection molding services. We offer a complete manufacturing solution that covers every aspect of raw material verification, tool making, part fabrication, finishing, and final inspection. Our international team of manufacturing experts is committed to providing you with the highest level of professional support for injection molding services of any size or complexity.

Digital manufacturing for plastic prototypes and on-demand production parts in as fast as 2 business days. We provide expert engineering reviews and $500 off your first mold. Dozens of materials and finishes are available.

What Is Injection Molding?

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. This process quickly repeats hundreds or thousands of times, amortizing the cost of the mold tool and driving down the cost of each unit to a few dollars or less. And it is the most cost-effective way to make a plastic part at scale. Injection molding also has the highest variety of materials, colors, cosmetics, polishes, and surface textures when compared to CNC machining or even 3D printing.

Crown Part’s injection molding service is a service that provides on-demand prototyping and production molding. We provide expert consultation on every injection mold quote and a project manager on every order dedicated to moving your part from design to production at the best possible price. Our team has experience in every industry, especially medical injection molding and liquid silicone rubber molding.

Injection Molding Processes

The injection molding process requires an injection molding machine, raw plastic material, and a machined mold. The raw plastic material is first melted in the injection unit then injected into the mold — most often machined from steel or aluminium — where it cools and solidifies into the final plastic part.

Go from prototyping to on-demand manufacturing in days for affordable, high-quality molded parts. Even better, once you move to on-demand manufacturing tools, your prototyping tools are free. Crown Part can also provide you with free design consultation services, which can greatly speed up the manufacturing process, allowing for greater supply chain flexibility, more consistent parts, and making certification a breeze.

- Plastic Injection Molding

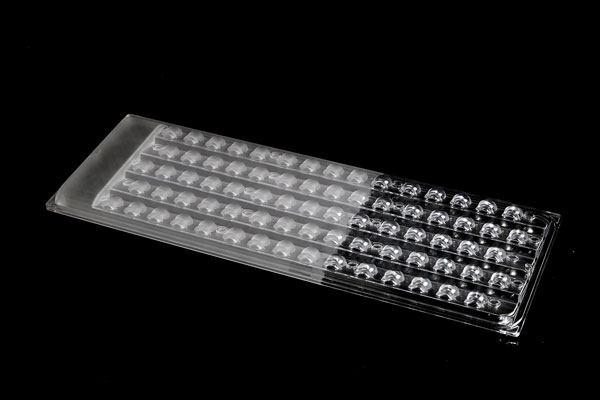

Plastic injection molding is a manufacturing process in which resin in a vat is heated to a molten state and then injected into a mold to form the final production-grade thermoplastic part. And it’s also a steel tool with short lead times, ideal for prototyping, design validation, and bridge production.

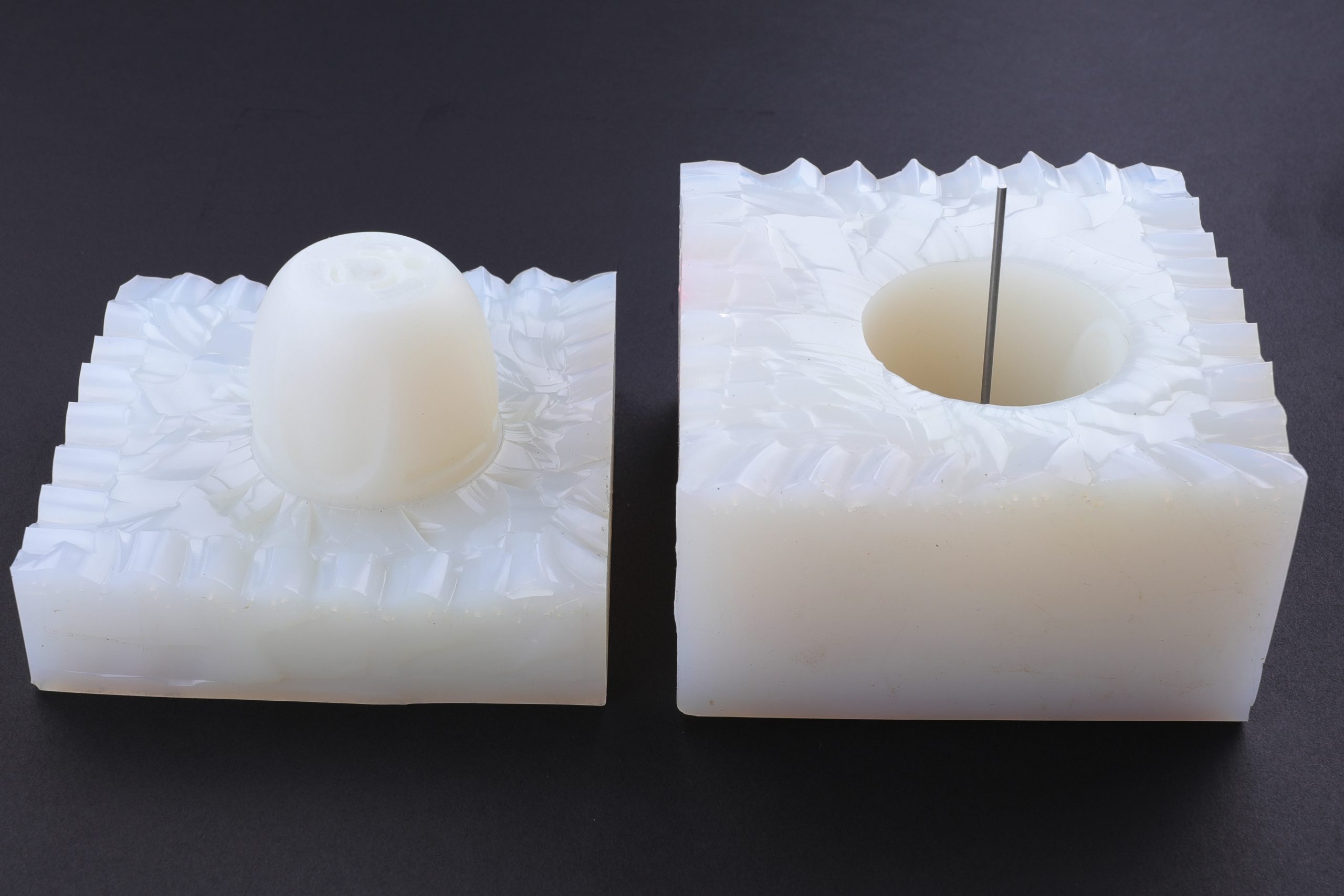

- Liquid Silicone Rubber Molding

Liquid Silicone Rubber (LSR) molding, sometimes known as Liquid Injection Molding (LIM), is a thermoset process of two compounds mixed and then heat-cured inside the mold using a platinum catalyst to create flexible silicone parts. A low compression set and the ability to resist extreme temperatures make LSR moldings durable and ideal for challenging applications. LSR elastomer offers exceptional optical clarity, durability, and design flexibility while maintaining excellent mechanical properties across a wide range of temperatures (-50oC to 250oC). LSR injection molding is suitable for manufacturing complicated geometries and can combine multiple functional elements into a single part due to its design and tooling flexibility. LIM provides considerable advantages in terms of product dependability and the total cost of tooling.

- Overmolding & Insert Molding

Overmolding and insert molding are two-part injection molding processes where one material is overlaid onto a second substrate part or metal insert to create a single component. Overmolding means that rubber or silicone molding over an existing plastic part. Insert Molding means that plastic injection molding around a preformed, often metal threaded, insert.

Injection Molding Materials

If you are still struggling with material selection, Crown Part can end it for you. We have wide selection of more than 100 thermoplastic and thermoset materials.

- ABS

- PC

- Acetal

- Acetal Copolymer

- Acetal Homopolymer/Delrin

- ETPU

- HDPE

- LCP

- LDPE

- LLDPE

- Nylon

- PBT

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- PMMA (Acrylic, Plexiglas)

- Polycarbonate

- Polypropylene

- PPA

- PPE/PS

- PS

- PSU

- TPU

- Standard silicone (30, 40, 50, 60, and 70 durometers)

- Medical-grade silicone

- Optical-grade silicone

- Fluorosilicone (fuel and oil resistant)

Advantages Of Injection Molding

Injection molding is plastic manufacturing process that can produce high quality parts at scale. It’s typically used for low- to high-volume production. What’s more, our aluminum tooling can also make prototyping runs economical.

Advantages as below:

- Low cost at higher volumes

- Large selection of thermoplastic and thermoset materials

- Exceptional part cosmetics and Excellent surface quality

- Overmolding for more design options

- Multi-cavity and family tools

- Stable and Repeatable

- Low scrap rate

Applications of Injection Molding

Injection molding is widely used for plastic part production in medical, consumer, and automotive industries.

Typical parts include:

- Housings

- Brackets

- Gears

- Single-use medical parts

- Electrical connectors

- Syringes

- Containers

Let's Start a New Project Today

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Rapid tooling and molds design

Our experienced can help you from molds design to products manufacturing. The only thing you need to do is to provide the drawing and 3d model to us.

One stop and in-house manufacturing services

We have various workshop to help you achieve your projects by our in-house production from molds production to products production.

Automatic production help you save costs

To guarantee the quality and cost reduction, we imported many industrial robotics to help feed material and pick up final products.

A full suite of finishing services

Most CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.