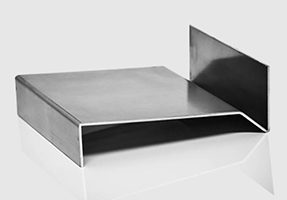

Sheet Metal

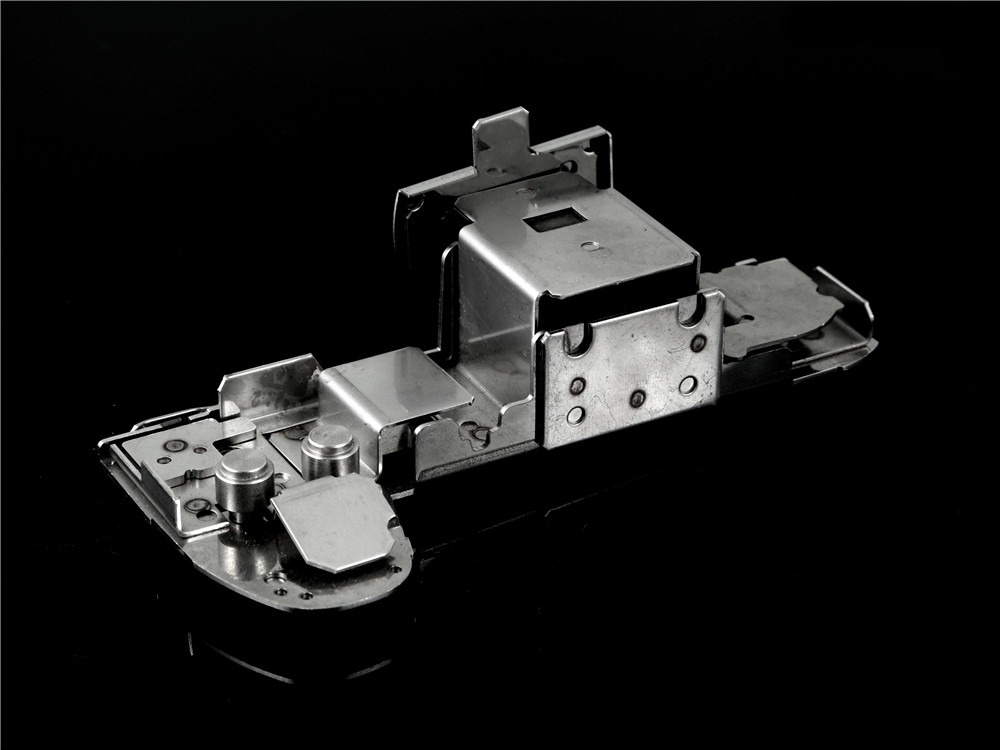

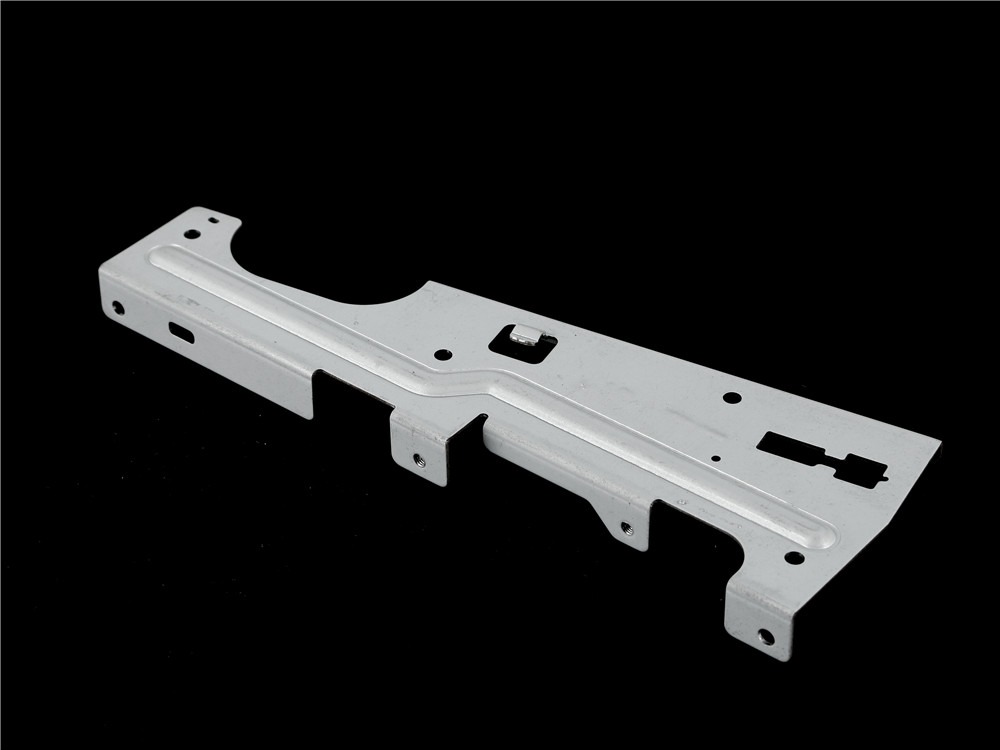

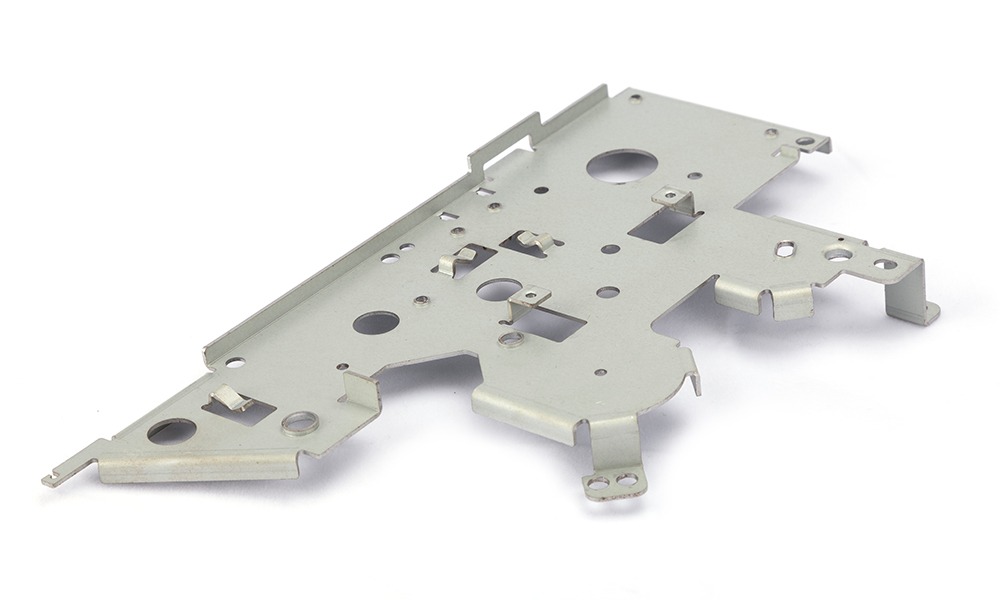

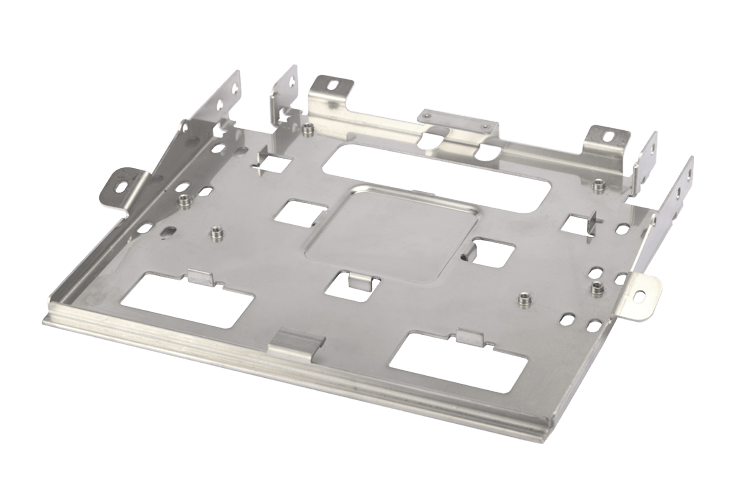

Custom Sheet Metal Services

If you are looking for a sheet metal prototyping solution that is both economical and quick, you should consider Crown part. We can produce sheet metal parts of high quality and cut various materials for our customers with great efficiency. We can work with different raw materials, such as stainless steel, aluminum, brass, copper, steel, plastic and more. We also offer finishing services such as polishing, painting, sandblasting, electroplating, anodizing, powder coating and more to improve the appearance of your parts. Our sheet metal fabrication services can deliver custom sheet metal components that meet your specifications for various industries, such as automotive, medical, aerospace, electronics, food, construction, security, marine and more. We use powerful CNC lasers or water jets to cut sheets or blanks of different sizes and shapes. Our CNC cutting services can handle a wide range of materials using laser cutting, water jetting and other methods.

How to choose sheet metal materials?

Sheet metal is a common form of raw material that is used in sheet metal fabrication. It usually comes in thicknesses between 0.15mm and 6 mm.

One of the most popular options is stainless steel grade 304, but grade 316 is also used for chemical and marine products.

Aluminum: Al 5052, 6061

Copper: C101, C110, brass (C260)

Stainless Steel: SS 301, 304, 316/316L

Steel: low carbon steel Types of Sheet Metal Finishes You can choose from the following sheet metal finishing options or contact us for a quote.

Post-processing

Crown offers a wide range of surface finishes that can enhance the look and performance of your sheet metal parts.

Bead Blast, Anodize, Plating (Nickel Plating, Silver Plating, etc.), Powder Coating, Chromate, Custom finishing services

Benefits of Sheet Metal Fabrication

High flexibility and durability to withstand forces and last for a long time. Reduced machining time to cut or bend the metal, lower the production cost.

Easy to handle custom simple or complex projects, whether prototypes or large scale Standard sheet metal thickness used in laser cutting or bending High strength and high resistance to corrosion, sun, and moisture.

Let's Start a New Project Today

Why choose us?

Crown Parts CNC machining services are optimized for speed, flexibility, and superior quality no matter the volume of parts. Here’s what sets us apart.

Industry-Leading CNC machining equipment

Imported 5-axis CNC machining centers running the most advanced AutoDesk and Vericut software. Exclusive Guhring cutting tools from Germany for the finest tool performance and longevity.

Intelligent pricing for every CNC machining project

Offering you a proprietary, patent-pending AI quotation algorithm. The power of machine learning gives you fast and accurate CNC machining quotes without guesswork.

Comprehensive raw material testing and verification

No one in the industry offers more dependable positive material identification (PMI). You can proceed with full confidence that your parts will meet all of your material specifications and regulatory compliance requirements.

A full suite of finishing services

Most CNC machined parts require some form of post-finishing before they’re ready to be put to use. From bead blasting to polishing, anodizing to plating, laser etching and to painting, we offer every surface treatment you need to make a great finished part.

Request For A Quote

You may request for a quote through e-mail ID or call us. Our team will reply you within 24 hours.

Crown Services

Industry

Resource

Contact

+86 19926645292

info@crown-part.com

Factory Address

F1 and F2, Bldg B., Shangnan Jinyuda Industrial Park,

Shangliao Community, Xinqiao Street,

Baoan District, Shenzhen 518000, China

Error: Contact form not found.